Blog

HYPERTHERM Distributor UAE: Powermax Plasma Systems Explained

When it comes to high-performance plasma cutting solutions, businesses across the UAE rely on trusted distributors who deliver genuine equipment, expert guidance, and reliable after-sales support. As a leading Fabricast partner, we supply advanced plasma cutting systems from Hypertherm, including the globally recognized Hypertherm Powermax range. In this guide, we…

BODOR Laser Cutting Equipment Distributors: Your Trusted Source for Advanced Cutting Solutions

In today’s fast-evolving manufacturing industry, precision and speed are essential for staying competitive. High-performance laser cutting technology plays a crucial role in achieving clean cuts, reduced waste, and maximum productivity. As one of the leading BODOR laser cutting equipment distributors, Fabricast delivers advanced cutting solutions designed to meet the growing…

MEGMEET Welding Machines in Kuwait: Advanced Technology for Industrial Excellence

In today’s competitive industrial landscape, welding technology plays a critical role in ensuring precision, strength, and efficiency. Businesses across Kuwait are increasingly choosing MEGMEET welding machines for their reliability, advanced features, and superior performance. At Fabricast, we proudly supply high-performance MEGMEET welding machines in Kuwait, delivering cutting-edge solutions for fabrication,…

BODOR Laser Cutting Equipment Distributors: Supplying High-Precision Fiber Laser Machines

In today’s competitive manufacturing and metal fabrication industry, precision, speed, and efficiency are critical for success. Advanced fiber laser technology has transformed how industries process sheet metal, stainless steel, aluminum, and other materials. Among global laser cutting brands, BODOR stands out for its innovation, smart automation, and high-performance fiber laser…

KEMPPI Welding Equipment for MIG, TIG & ARC Welding: A Buyer’s Guide

In today’s competitive fabrication and industrial landscape, selecting the right welding equipment is critical for productivity, weld quality, and operational efficiency. Among the world’s leading welding technology brands, KEMPPI Welding Equipment stands out for its Finnish engineering excellence, digital innovation, and superior arc performance. At Fabricast, we understand that choosing…

JASIC Welding Equipment: Smart Features & Safety Innovations

In today’s fast-evolving industrial landscape, welding technology is no longer just about generating an arc and fusing metals. Modern fabrication demands precision, energy efficiency, portability, digital control, and above all — safety. This is where JASIC Welding Equipment stands out as a global leader in advanced inverter welding solutions. At…

TAG Pipe Equipment Distributors in Qatar: Complete Range of Cold Cutting and Beveling Machines

In industries where precision, safety, and efficiency are critical, pipe cutting and beveling must be performed with the highest level of accuracy. Traditional hot cutting methods often introduce safety risks and material distortion—making cold cutting and beveling solutions the preferred choice for modern industrial projects. TAG Pipe Equipment is globally…

Harris Distributors Kuwait: Complete Range of Regulators, Torches, and Safety Gear

In industrial welding, cutting, and gas control applications, safety and precision are non-negotiable. The quality of regulators, torches, and safety equipment directly affects operational efficiency and worker protection. Harris, a globally trusted brand, is known for delivering high-performance gas control solutions—and in Kuwait, Fabricast stands as a reliable distributor, supplying…

ESAB Welding Machine Distributors: Complete Guide to Products, Support, and Service

In today’s fast-paced industrial environment, welding quality, reliability, and efficiency directly impact project success. Choosing the right welding equipment is important—but selecting a trusted ESAB welding machine distributor is equally critical. As a globally recognized brand, ESAB delivers advanced welding and cutting solutions, and Fabricast plays a key role in…

Welding Equipment Rentals in Qatar: Reliable and Cost-Effective Solutions for Industrial Projects

Industrial and construction projects in Qatar demand dependable welding equipment that can perform efficiently under challenging conditions. Investing in expensive machinery is not always practical, especially for short-term or specialized requirements. This is where welding equipment rentals in Qatar become an ideal solution. Fabricast, a trusted industrial equipment supplier, offers…

Welding Machine Rentals in Kuwait: Reliable Equipment for Industrial Projects

Industrial projects demand reliable welding equipment that delivers consistent performance while keeping operational costs under control. For businesses looking for flexibility and efficiency, welding machine rentals in Kuwait offer a practical solution. Fabricast, a trusted industrial equipment provider, delivers high-quality welding machine rental services tailored to meet the needs of…

Hyundai Welding Suppliers: Trusted Source for High-Performance Welding Solutions

In today’s demanding industrial landscape, welding quality plays a critical role in ensuring safety, durability, and operational efficiency. As one of the most trusted names in welding technology, Hyundai welding products are known for their reliability and performance. Fabricast, a leading industrial solutions provider, proudly stands among the trusted Hyundai…

ESAB Welding Qatar: Trusted Welding Solutions for Industrial Excellence

In Qatar’s rapidly growing industrial and construction sectors, reliable welding solutions are essential for maintaining quality, safety, and productivity. ESAB Welding products are globally recognized for their innovation, durability, and performance. At Fabricast, we proudly supply ESAB welding solutions in Qatar, supporting industries with world-class welding equipment and consumables designed…

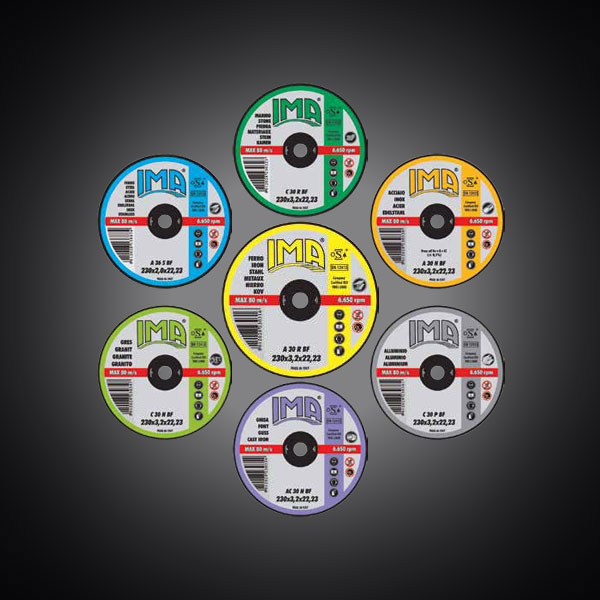

IMA Abrasives Distributors Kuwait: Your Reliable Partner for Quality Abrasive Solutions

In industrial sectors where precision, efficiency, and surface quality are essential, choosing the right abrasive products makes a significant difference. IMA Abrasives is a globally recognized brand known for delivering consistent and high-performance abrasive solutions. In Kuwait, Fabricast stands as a reliable distributor of IMA Abrasives, providing industries with trusted…

IMA Abrasives Distributors Qatar: High-Quality Abrasive Products for Precision Grinding and Cutting

Precision grinding and cutting are essential processes in modern industrial operations, where accuracy, efficiency, and surface quality directly impact project outcomes. IMA Abrasives is a globally trusted brand known for delivering high-performance abrasive products, and Fabricast is a reliable distributor of IMA Abrasives in Qatar, supplying industries with premium abrasive…

Harris Welding Consumables Qatar: Premium Solutions for Professional Welding Applications

In today’s demanding industrial environment, welding quality plays a critical role in ensuring safety, durability, and performance. Harris Welding Consumables are globally recognized for their reliability, precision, and superior performance. In Qatar, Fabricast proudly supplies Harris Welding Consumables, offering professional welders and industries access to world-class welding solutions tailored to…

JASIC Welding Equipment Qatar: Advanced and Reliable Welding Solutions for Industrial Applications

In industries where precision, efficiency, and durability are essential, choosing the right welding equipment plays a crucial role in project success. As a trusted supplier of JASIC Welding Equipment in Qatar, Fabricast provides advanced welding solutions designed to meet the demanding requirements of industrial, fabrication, and construction applications. About JASIC…

IMA Abrasives Distributors UAE: Reliable Abrasive Solutions for Industrial Grinding and Finishing

In industrial environments where surface quality, efficiency, and durability matter, choosing the right abrasives is essential. As trusted IMA Abrasives Distributors in the UAE, Fabricast supplies high-quality abrasive products designed to deliver consistent performance for grinding, cutting, and finishing applications across multiple industries. About IMA Abrasives IMA Abrasives is a…

TAG Pipe Equipment Distributors in Qatar: Trusted Solutions for Precision Pipe Cutting and Beveling

In industries where accuracy, efficiency, and reliability are critical, having the right pipe preparation equipment makes a significant difference. As one of the leading TAG Pipe Equipment Distributors in Qatar, Fabricast supplies advanced solutions for precision pipe cutting, beveling, and machining to meet the demands of oil & gas, petrochemical,…

Hyundai Welding Consumables: Reliable Welding Solutions for Industrial Excellence

In today’s competitive industrial landscape, welding quality plays a vital role in ensuring structural integrity, operational safety, and long-term performance. The choice of welding consumables directly affects productivity, weld strength, and overall project efficiency. Hyundai Welding Consumables, known globally for their consistency and performance, are trusted by professionals across industries.…

ESAB Welding Consumables Qatar: High-Quality Solutions for Reliable and Efficient Welding

In industrial and fabrication environments, the quality of welding consumables directly influences weld strength, durability, and overall project success. From structural steel to critical pipeline applications, using trusted consumables is essential. ESAB, a global leader in welding technology, offers a comprehensive range of premium welding consumables designed to deliver consistent…

ESAB Welding Machine Distributors: Your Trusted Source for Advanced Welding Solutions

In modern industrial operations, welding is more than just a joining process—it is a critical factor that determines structural strength, safety, and long-term performance. Choosing the right welding equipment and, more importantly, a reliable distributor, directly impacts project efficiency and quality. As one of the dependable ESAB welding machine distributors,…

TAG Pipe Equipment Suppliers Qatar: Trusted Solutions for Industrial Pipe Fabrication

Industrial pipe fabrication plays a critical role in sectors such as oil & gas, petrochemicals, power generation, and infrastructure development in Qatar. Achieving precision, safety, and productivity requires advanced pipe cutting, bevelling, and welding equipment. As a trusted TAG Pipe Equipment Supplier in Qatar, Fabricast delivers high-performance solutions designed to…

Harris Equipment Distributors: Your Trusted Source for Professional Welding and Gas Control Solutions

In industrial welding and cutting operations, precision, safety, and reliability are non-negotiable. From fabrication workshops to large-scale industrial projects, the quality of gas control and welding equipment directly impacts productivity and operational safety. As a trusted Harris Equipment Distributor, Fabricast supplies industry-leading Harris products that deliver dependable performance across a…

ESAB Welding Distributors: Your Trusted Partner for High-Quality Welding Solutions

In today’s demanding industrial environment, welding quality, reliability, and efficiency are critical to project success. From construction and fabrication to oil & gas and heavy engineering, industries require proven welding solutions that deliver consistent performance. As an authorized ESAB Welding Distributor, Fabricast stands as a trusted partner, supplying world-class welding…

Lincoln Welding Machine for MIG, TIG, and Stick Welding Explained

When it comes to precision welding, durability, and performance, Lincoln welding machines are trusted by professionals across industries. Whether you are working in fabrication, construction, automotive repair, or heavy manufacturing, Lincoln Electric offers versatile welding solutions that support MIG, TIG, and Stick welding with consistent results. This guide explains how…

Diesel Generator Systems: Powering Industries with Efficiency and Durability

In today’s fast-paced industrial environment, uninterrupted power is not a luxury—it’s a necessity. From manufacturing plants and construction sites to infrastructure projects and remote operations, reliable power solutions keep industries running smoothly. Fabricast delivers robust diesel generator systems designed to provide dependable, efficient, and long-lasting power for diverse industrial applications.…

Bodor Laser Welding Machines – High-Tech Solutions for Modern Manufacturing

Introduction In fast-moving manufacturing hubs like the UAE and Qatar, staying competitive means investing in precision, speed, and reliability. Bodor Laser Welding Machines deliver on all three — offering high-precision welding, low operating costs, and versatile process control. Fabricast, a trusted supplier in the region, brings Bodor’s advanced laser welding…

Megmeet TIG Rentals: Premium TIG Welding Machines for Every Project

When precision and weld quality matter, TIG welding becomes the preferred choice for professionals. Whether you’re working on stainless steel, aluminum, copper, or exotic alloys, having a reliable TIG welding machine is essential. At Fabricast, we offer high-performance Megmeet TIG Rentals to support fabrication workshops, maintenance teams, construction sites, and…

Laser Cutting Machine UAE: Precision Cutting Solutions for Every Industry

In today’s fast-paced manufacturing environment, accuracy and efficiency are essential. Businesses across the UAE—from fabrication workshops to large industrial plants—are increasingly relying on laser cutting machines for clean, precise, and consistent metal cutting. At Fabricast, we supply premium laser cutting solutions designed to meet the demands of modern production. Whether…

Sinoars Welding Studs: High-Performance Fastening Solutions for Industrial Applications

When it comes to industrial welding fasteners, precision, durability, and reliability are non-negotiable. Sinoars Welding Studs have become a trusted choice across industries such as construction, fabrication, shipbuilding, oil & gas, and heavy engineering. At Fabricast, we are committed to supplying premium welding consumables, and Sinoars studs stand out as…

Lincoln Electric KSA: Powering Industrial Welding Solutions in Saudi Arabia

When it comes to reliable, high-performance welding equipment in Saudi Arabia, Lincoln Electric KSA stands as one of the most trusted names in the industry. As industries across the Kingdom rapidly expand—from oil & gas to construction, fabrication, and heavy engineering—the demand for world-class welding machines and consumables continues to…

Rotators Rental Saudi Arabia by Astra: High-Performance Welding & Pipe Rotators

In Saudi Arabia’s booming industrial landscape, efficiency, precision, and safety are critical to every welding and fabrication project. For companies looking to enhance productivity without the high investment cost of buying heavy equipment, rotators rental Saudi Arabia by Astra has become a go-to solution. As a trusted partner in industrial…

ESAB Welding Machine Rental : The Smart Choice for Reliable Industrial Welding in 2025

When it comes to high-performance welding solutions, ESAB stands out as one of the most trusted brands worldwide. In UAE rapidly growing industrial and construction sectors, many businesses are shifting from purchasing welding machines to renting ESAB welding equipment—a cost-effective and flexible choice for both short-term and long-term projects. If…

Welding Machine Rentals: Flexible, Cost-Effective Options for Professionals

In today’s fast-moving industrial environment, flexibility and cost-efficiency are just as important as performance and reliability. Whether you work in construction, manufacturing, oil & gas, shipbuilding, or general fabrication, having access to the right welding equipment can make all the difference. At Fabricast, we understand the real-world challenges professionals face,…

ESAB Welding Machine Rental : Power, Precision, and Productivity

In demanding industrial environments, welding performance directly impacts productivity, safety, and project timelines. Choosing the right equipment is critical, and ESAB welding machines are globally recognized for their power, precision, and reliability. With ESAB Welding Machine Rental services from Fabricast, businesses can access world-class welding technology without the high cost…

Sinoars Welding Studs: Enhancing Quality and Durability in Industrial Welding

In the fast-paced world of industrial fabrication, the quality of every weld, joint, and fastening component matters. Whether it’s construction, shipbuilding, oil & gas, or heavy manufacturing, reliable welding accessories are essential to maintain safety, performance, and long-lasting structural integrity. At Fabricast, a trusted supplier of welding solutions in the…

Jasic MIG KSA: High-Quality MIG Welding Machines for Professional Fabricators

In the rapidly growing industrial and fabrication sectors of the Kingdom of Saudi Arabia, the demand for high-performance, durable, and cost-efficient welding machines continues to rise. Among the top brands meeting these expectations, Jasic stands out with its advanced MIG welding systems. Through trusted distributors like Fabricast, professional welders and…

Bodor Laser Welding Machines – Precision Engineering Meets Industrial Power

In today’s fast-paced manufacturing world, industries demand welding solutions that deliver accuracy, speed, and long-term reliability. Bodor Laser, a global leader in laser technology, has redefined industrial welding with its advanced laser welding machines—offering unmatched precision and consistent performance. Through Fabricast, Bodor’s trusted distributor in the UAE, businesses can now…

Hypertherm Plasma Cutter in UAE – Power, Precision, and Reliability

When it comes to industrial cutting solutions, Hypertherm stands tall as a global leader. For the UAE fabrication industry, where every cut matters, Hypertherm’s plasma systems offer the perfect mix of power, precision, and reliability. Through its authorized distributor Fabricast in the UAE, Hypertherm provides local access to its advanced…

Jasic MIG KSA – The Smart Choice for Industrial Fabrication

In today’s competitive industrial landscape, the demand for efficient, high-quality welding equipment has never been greater. From construction and manufacturing to oil and gas, reliable welding performance directly impacts project timelines and overall productivity. That’s where Jasic MIG Welding Machines in KSA stand out — combining cutting-edge inverter technology, energy…

Lincoln Welding Machine – Innovation that Powers Industrial Welding

In the world of metal fabrication and industrial welding, performance, reliability, and precision define success. That’s why professionals across the globe trust the Lincoln Welding Machine, a name synonymous with innovation and quality. At Fabricast, we proudly supply Lincoln Electric’s advanced welding solutions across the Middle East—helping industries achieve unmatched…

Sinoars Welding Studs – The Trusted Choice for Industrial Welding Applications

In today’s demanding industrial environments, reliability and precision are essential when it comes to welding components. Fabricast a leading supplier of welding equipment and accessories in the Middle East, proudly offers Sinoars Welding Studs—engineered for superior performance, strength, and consistency across a wide range of applications. Whether you’re working in…

ESAB Welding Machine Rental – Reliable Welding Solutions for Every Project

In industrial and construction projects, welding quality and reliability are critical to overall success. Using the right equipment ensures strong welds, improved productivity, and reduced downtime. ESAB Welding Machine Rental from Fabricast offers dependable, high-performance welding solutions tailored to meet the needs of projects of all sizes. Why Choose ESAB…

Hypertherm Plasma Cutter in UAE – Cutting-Edge Technology for Metalwork

Power. Precision. Performance – Redefining Metal Cutting with Hypertherm When it comes to metal fabrication, precision and efficiency are everything. Whether you’re shaping intricate parts or cutting through thick steel plates, you need tools that deliver accuracy and reliability every time. That’s where the Hypertherm Plasma Cutter, available at Fabricast…

Bodor Laser Welding Machines – The Future of Industrial Welding Solutions

Precision. Power. Performance — Redefining Industrial Welding with Bodor In today’s fast-paced industrial world, efficiency, precision, and quality are not just goals — they are necessities. Bodor Laser Welding Machines, now available at Fabricast, are setting new benchmarks in welding technology. Designed for versatility and built for reliability, these machines…

TAG Pipe Bevelling and Pipe Cold Cutting Machines – Efficiency Meets Accuracy

Precision, efficiency, and safety are essential in modern pipe fabrication and maintenance. That’s why professionals across industries trust TAG Pipe Bevelling and Pipe Cold Cutting Machines, available through Fabricast, to deliver exceptional performance and accuracy. Designed for reliability and ease of use, TAG equipment ensures high-quality results even in the…

Jasic TIG Rentals – High-Quality Welding Machines for Hire

When precision and reliability matter most, professional welders trust Jasic TIG welding machines for their advanced technology and consistent performance. At Fabricast, we make it easy for businesses and professionals to access high-quality Jasic TIG welders for rent, ensuring top results without the high upfront investment. Whether you’re handling stainless…

Ador Consumables in UAE and Qatar: High-Quality Solutions for Welding Professionals

When it comes to achieving precision, strength, and durability in welding, the right consumables make all the difference. Ador Welding Consumables, now available in the UAE and Qatar through Fabricast, are designed to deliver unmatched performance across various industrial and fabrication applications. Whether you’re working in construction, shipbuilding, oil &…

Shindaiwa Diesel Generator: Reliable Power for Every Industrial Application

In today’s fast-paced industrial world, uninterrupted power isn’t just a necessity — it’s the backbone of productivity, safety, and efficiency. Whether you’re running a construction site, manufacturing plant, or remote operation, having a dependable power source ensures that your business runs smoothly. That’s where Shindaiwa Diesel Generators make a difference.…

Kemppi Arc Welding Machine: Redefining Precision and Power in Welding

In modern fabrication and industrial projects, achieving precision, efficiency, and consistency in welding is crucial. Professionals across the globe trust Kemppi for delivering cutting-edge welding technology that meets the highest standards of performance and durability. At Fabricast, we are proud to supply Kemppi Arc Welding Machines across the Qatar, empowering…

Lincoln Welding Machines: Power, Precision, and Performance for Every Project

In the world of welding, power, reliability, and precision are non-negotiable. Whether you’re working on a large-scale industrial project or a small fabrication job, the right welding equipment determines the quality and efficiency of your results. That’s where Lincoln Welding Machines come in — a global leader known for innovation,…

Rotators Rental: Reliable Tools for Heavy-Duty Industrial Tasks

In heavy industries like metal fabrication, construction, and shipbuilding, precision and efficiency are crucial. One of the key tools that help achieve these goals is a welding rotator. Astra rotators, known for their robust design and smooth operation, have become a preferred choice for professionals worldwide. At Fabricast, we provide…

ESAB Machine Rental Services – High Performance, Low Cost

When it comes to welding, every project demands reliability, precision, and performance. That’s where ESAB welding machines stand out — known globally for their innovation, strength, and consistent quality. At Fabricast, we make it easier for industries across the UAE and Qatar to access this power through our ESAB machine…

Jasic MIG Rentals: High-Performance Welding Made Easy

In today’s fast-paced industrial world, efficiency and precision are key to delivering top-quality welding results. That’s why professionals across the UAE and Qatar trust Fabricast for Jasic MIG welding machine rentals — combining reliability, performance, and cost-effectiveness in one solution. Whether you’re working on a construction site, fabrication shop, or…

Hyundai Welding Consumables Distributors in UAE, Qatar, Saudi Arabia, and Kuwait

Fabricast is the premier distributor of Hyundai welding consumables across the UAE, Qatar, Saudi Arabia, and Kuwait, offering industrial clients access to high-performance welding solutions backed by trusted technology and logistical excellence. Wide Range of Hyundai Welding Consumables Fabricast supplies a comprehensive selection of Hyundai consumables tailored for various industrial…

Top Astra Welding Machines Available for Rental in UAE, Qatar

Fabricast offers a premium selection of Astra welding machines available for rental across the UAE, Qatar, Saudi Arabia, and Kuwait. Their rental inventory spans high-capacity automated systems, robust industrial-grade welders, and specialized accessories, meeting the needs of diverse industries from construction to heavy fabrication. Leading Astra Welding Machines Fabricast’s Astra…

Welding Machines Rentals in UAE: Fabricast Delivers Reliable Solutions

In the dynamic industrial and construction landscape of the UAE, access to the right equipment is critical for completing projects efficiently and cost-effectively. When it comes to welding machines, investing in brand-new equipment isn’t always the most practical choice. That’s why Fabricast, a trusted name in welding solutions, offers reliable…

Why Fabricast is the Go-To Distributor for ESAB Welding Rentals

In today’s competitive industrial market, choosing the right welding equipment can make all the difference in productivity, cost-efficiency, and project success. ESAB, a global leader in welding and cutting solutions, is trusted by professionals across industries for its durability, advanced technology, and consistent performance. But where should you go when…

Environmental Best Practices: Sustainable Welding and Cutting Solutions

In today’s rapidly evolving industrial world, sustainability has become a central focus across all sectors—including welding and cutting. These essential fabrication processes, while vital to industries like construction, automotive, and manufacturing, can also have significant environmental impacts. From energy consumption to fumes and waste, traditional practices often contribute to resource…

Safe Operation of Advanced Cutting Tools: Best Practices for Professionals

Cutting tools have evolved significantly in recent years. From precision CNC cutters to handheld laser and plasma devices, advanced cutting technology allows for greater accuracy, speed, and efficiency across industries such as manufacturing, construction, automotive, and aerospace. While these tools offer remarkable capabilities, they also demand a higher level of…

Welding Safety Essentials: Current Hazards and Solutions

Welding is one of the most critical processes in industries ranging from construction and automotive to shipbuilding and manufacturing. However, it’s also a high-risk activity where safety cannot be compromised. Modern welding environments involve multiple hazards—some visible, others invisible—that can cause serious injuries or long-term health issues if not addressed…

Practical Applications of Waterjet and Plasma Cutting

In the world of modern fabrication and manufacturing, precision and efficiency play a key role. Two cutting technologies that have revolutionized the industry are waterjet cutting and plasma cutting. Both methods offer unique advantages, making them suitable for a wide range of applications in metalworking, construction, automotive, aerospace, and even…

Extending the Lifespan of Your Welding and Cutting Equipment

Welding and cutting machines are valuable investments in any fabrication shop or industrial setup. Whether you rely on MIG, TIG, Stick welders, or plasma cutters, keeping your equipment in good condition directly impacts productivity, safety, and cost efficiency. With the right practices, you can extend the lifespan of your welding…

Comparing Manual vs. Automated Welding: Pros, Cons, and Cost Analysis

Welding is the backbone of modern manufacturing, construction, and fabrication. From automotive parts to skyscrapers, strong and precise welds ensure the safety, durability, and performance of structures and machinery. But with the rise of advanced robotics and automation, many businesses face a key decision: Should they stick with manual welding…

Precision in Practice: Benefits of Handheld Laser Welders

In today’s fast-paced manufacturing and fabrication industries, precision and efficiency are not just advantages—they’re necessities. Traditional welding methods, though reliable, often fall short when it comes to speed, accuracy, and flexibility. That’s where handheld laser welders step in, offering a revolutionary approach that combines cutting-edge technology with ease of use.…

Essential Tools Every Welder Should Own

Welding is more than just joining metals—it’s an art, a skill, and a craft that requires the right set of tools. Whether you’re a beginner welder setting up your first workshop or a seasoned professional upgrading your gear, having the right tools not only makes your work easier but also…

A Buyer’s Guide: Choosing the Right Welding Machine for Your Workshop.

Setting up a workshop—whether for professional fabrication or personal DIY projects—requires choosing the right welding machine. With so many options available in the market, it can feel overwhelming to decide which model suits your needs. The right choice will depend on your budget, the materials you work with, and the…

Top Welding Equipment Brands to Watch in 2025

Welding technology has evolved rapidly over the last decade, with manufacturers focusing on innovation, automation, and sustainability. In 2025, the industry is seeing a growing demand for high-performance equipment that can support advanced manufacturing, construction, automotive, and even renewable energy sectors. Whether you’re a professional welder, a fabricator, or an…

Automation for Small-to-Medium Enterprises: Making Robotics Accessible

In recent years, automation and robotics have transformed industries by increasing efficiency, reducing operational costs, and improving quality. However, the perception has long been that robotics is reserved for large corporations with deep pockets and highly specialized teams. Today, that landscape is changing. Small-to-medium enterprises (SMEs) are increasingly finding automation…

Smart Welding Systems: IoT and Real-Time Monitoring in Modern Weld Shops

The welding industry has been a cornerstone of manufacturing, construction, and infrastructure for decades. But in today’s digital era, welding is undergoing a transformation. With the integration of IoT (Internet of Things) and real-time monitoring technologies, weld shops are moving beyond traditional practices to embrace a new age of efficiency,…

Next-Gen Cutting: Advances in Laser, Plasma, and Waterjet Technology

In the modern manufacturing landscape, cutting technology plays a pivotal role in shaping materials with speed, precision, and efficiency. From aerospace components to intricate art installations, industries are constantly seeking methods that combine accuracy, cost-effectiveness, and versatility. Three technologies—laser cutting, plasma cutting, and waterjet cutting—have emerged as leaders in next-gen…

The Role of Laser Cutting & Welding in Manufacturing

In today’s competitive industrial landscape, precision, speed, and efficiency are key to staying ahead. Laser cutting and welding technologies have revolutionized manufacturing processes, enabling industries to achieve exceptional accuracy, minimal waste, and high production rates. From automotive and aerospace to electronics and medical devices, these laser-based processes are now at…

Laser Cutting Tips: Mastering High-Precision Countersinking

In the world of modern fabrication, laser cutting has revolutionized how we shape and finish materials. One advanced technique that can significantly improve assembly quality and aesthetics is high-precision countersinking. Whether you’re working with metals, plastics, or composite materials, mastering countersinking with a laser cutter requires the right settings, techniques,…

The Essential Guide to Choosing an Industrial Laser Cutting Machine

In the ever-evolving world of manufacturing and fabrication, laser cutting has revolutionized how industries cut, shape, and manipulate materials. Whether you’re a small-scale workshop or a large-scale production unit, choosing the right industrial laser cutting machine can significantly influence your efficiency, product quality, and bottom line. This essential guide will…

How Laser Bevel Cutting Works – A Precision Guide to Angled Cuts

In today’s world of advanced fabrication, laser cutting has emerged as one of the most precise and efficient methods for processing metals, plastics, and other materials. Among its specialized forms, laser bevel cutting plays a crucial role in industries requiring angled edges for weld preparation, complex assemblies, and aesthetic finishes.…

Welding Thin Sheets – Common Issues and How Laser Welding Offers Solutions

Introduction Welding thin sheets of metal is a common requirement in industries like automotive, aerospace, electronics, and precision manufacturing. However, working with thin materials (typically less than 3 mm thick) introduces unique challenges that can compromise the strength, appearance, and functionality of the final product. Traditional welding techniques often fall…

What Are the Safety Guidelines for Laser Welding?

Laser welding is a cutting-edge technology widely used in industries like automotive, aerospace, electronics, and medical devices. It offers high precision, deep penetration, and minimal distortion. However, due to the intense energy and potentially hazardous emissions involved, laser welding comes with its own set of safety challenges. Whether you’re a…

How Do You Maintain Welding Equipment to Ensure It Operates Safely and Efficiently?

Welding is a vital process across various industries—from construction and automotive to shipbuilding and manufacturing. But even the most skilled welder can’t perform quality work without well-maintained equipment. Regular maintenance of welding machines and tools is not just about prolonging their lifespan—it’s a matter of safety, efficiency, and cost-effectiveness. In…

Comparison of Minimum Achievable Tolerances Across Different Cutting Technologies

Precision in manufacturing isn’t just a luxury—it’s a necessity. Whether you’re crafting aerospace parts, medical instruments, or intricate electronics, achieving tight tolerances is critical for functionality, safety, and interchangeability. In this article, we explore and compare the minimum achievable tolerances across a range of popular cutting technologies to help engineers…

Manage Heat Buildup During Laser Welding, Ensuring Stable and Consistent Weld Quality

Laser welding is a highly precise and efficient joining process widely used in industries ranging from automotive and aerospace to medical device manufacturing. However, one of the most critical challenges in laser welding is managing heat buildup. If not controlled effectively, excessive heat can lead to warping, cracking, porosity, or…

ESAB Welding Equipment Distributors & Suppliers in UAE

ESAB Welding Equipment Distributors in UAE: Your Guide to Quality and Service When it comes to welding and cutting technology, ESAB stands as one of the world’s leading brands, renowned for its innovation, reliability, and broad product range. For professionals and businesses in the UAE, sourcing genuine ESAB welding equipment…

The Unsung Hero: Why a B&B Fixed Pipe Jack Is a Must-Have for Every Welder

In the world of pipe welding and fabrication, the final product gets all the glory—a clean, strong weld that holds under pressure. But behind every perfect joint is a team of tools working in unison, with the humble pipe jack playing one of the most critical roles. It’s the unsung…

The Plasma Advantage: Removing Spot Welds with the Powermax45 XP

Spot weld removal is a tedious but necessary task in many metalworking and automotive repair projects. The goal is to separate two pieces of metal by breaking the weld points, all while leaving the base material intact and ready for a new panel or repair. Traditionally, this has been a…

Five Potential Welding Safety Hazards to Avoid

Welding is a crucial and rewarding trade, but it’s not without its risks. The intense heat, bright light, and various byproducts of the process can pose serious safety hazards if proper precautions aren’t taken. Whether you’re a seasoned professional or just starting out, a constant awareness of potential dangers is…

Master the Angle: Your Jasic Beginner’s Guide to Corner Welding

Corner welds might seem intimidating at first, but for anyone starting out with a Jasic welder, they’re a fundamental skill that unlocks a world of fabrication possibilities. Whether you’re joining two pieces at a 90-degree angle for a box, a frame, or a workbench, mastering the corner weld is crucial.…

Weld Smart, Not Heavy: The Undeniable Advantages of Welding Equipment Rentals

For many businesses and individual welders, the default thought when needing welding equipment is to buy it. While outright ownership certainly has its place, the savvy professional is increasingly turning to an often-overlooked, yet incredibly powerful, alternative: welding equipment rentals. In today’s dynamic economic landscape, where projects fluctuate and technology…

Unlocking the Flame: A Deep Dive into Oxy-Fuel Torch Tip/Nozzle Preheat Design

The oxy-fuel cutting torch is a marvel of simplicity and raw power, capable of slicing through thick steel like butter. But the magic doesn’t just happen with a flick of a switch; it’s a carefully orchestrated dance of gases, ignited and shaped by the unsung hero of the operation: the…

Sealing Strength: Your Ultimate Guide to Container Welding

Containers, whether for shipping, storage, or specialized industrial applications, rely on one critical factor for their integrity: expert welding. A poorly welded container is a liability, leading to leaks, structural failure, and potential hazards. This guide delves into the essential aspects of container welding, covering key techniques, necessary equipment, and…

A Guide to Choosing the Best Equipment for Construction

The construction industry is built on strength, precision, and durability – qualities that are often achieved through expert welding. But to achieve those expert welds, you need the right tools. Choosing the best welding equipment for construction isn’t a one-size-fits-all decision; it requires careful consideration of various factors. This blog…